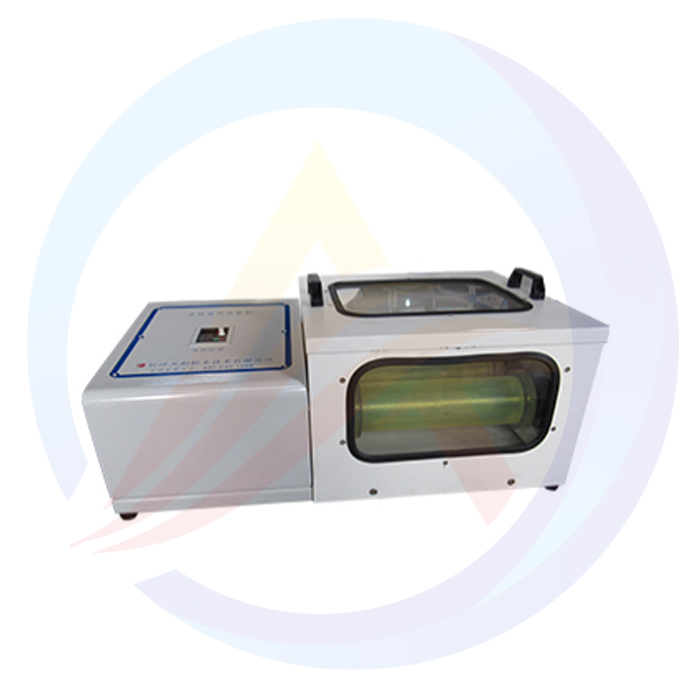

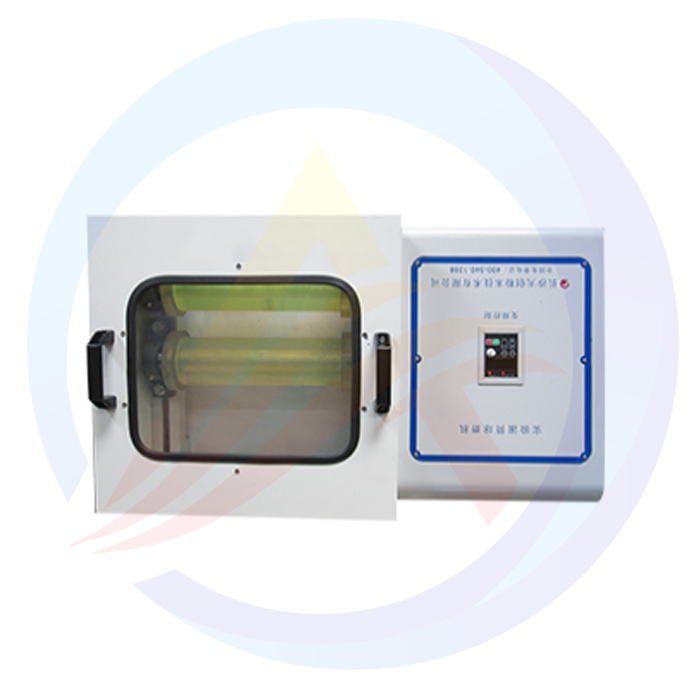

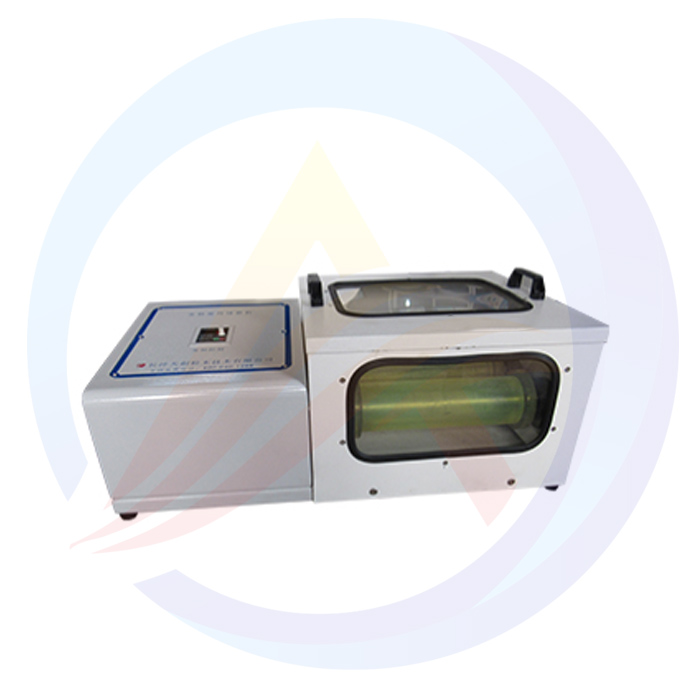

1. Compact structure, easy operation2. High efficiency and uniform granularity

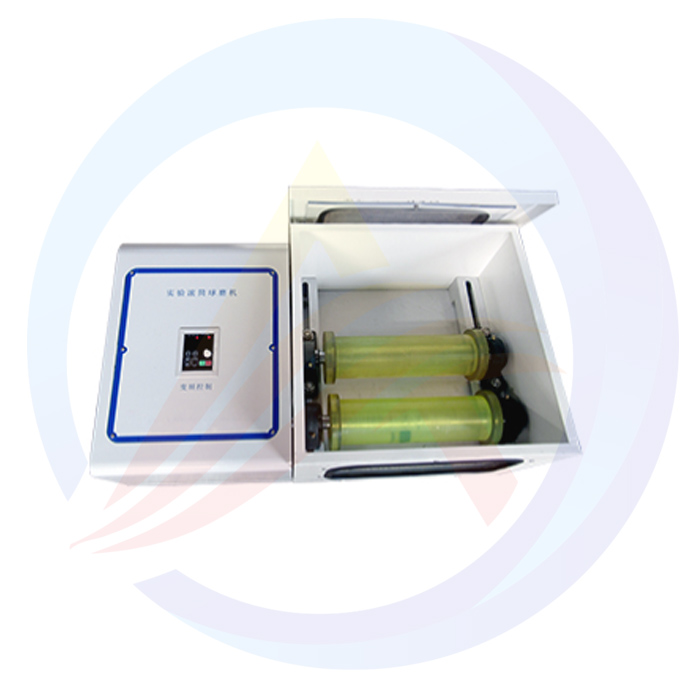

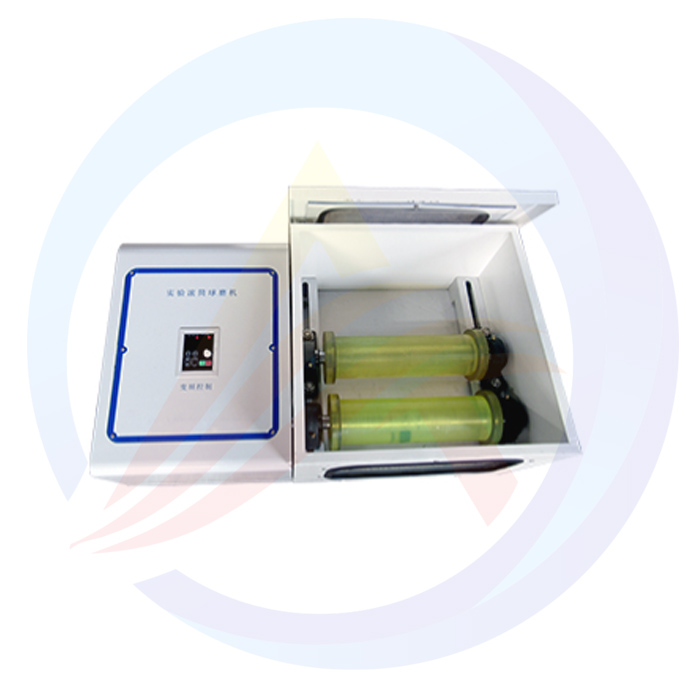

3. Milling pot in different size can be put on the driven rubber roller within a certain range by means of adjusting space between the rubber rollers.

The Jar Ball Mill Machine (a type of efficient grinding equipment) is composed of a rotating tank filled with grinding media (such as steel balls or ceramic balls). By rotating the tank and causing the media to collide and rub against the materials, it enables the fine grinding and mixing of the materials, with particle sizes reaching the micrometer level. It is suitable for applications in fields such as mining, ceramics, and chemicals, and can be operated either dry or wet. The operation is simple, the grinding is uniform, and it is widely used in laboratory small-scale tests and industrial production.

A Jar Ball Mill Machine is a device for grinding and mixing materials. It consists of a rotating tank and grinding media like steel balls. By driving the media to move, it uses impact, friction and shearing force to crush materials. It's widely used in chemical, ceramic, pharmaceutical and other industries, and can work in dry or wet conditions.