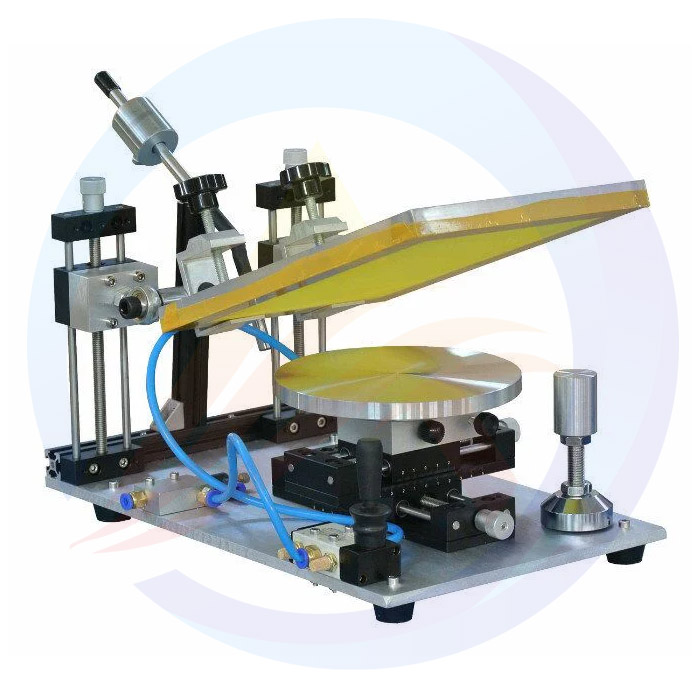

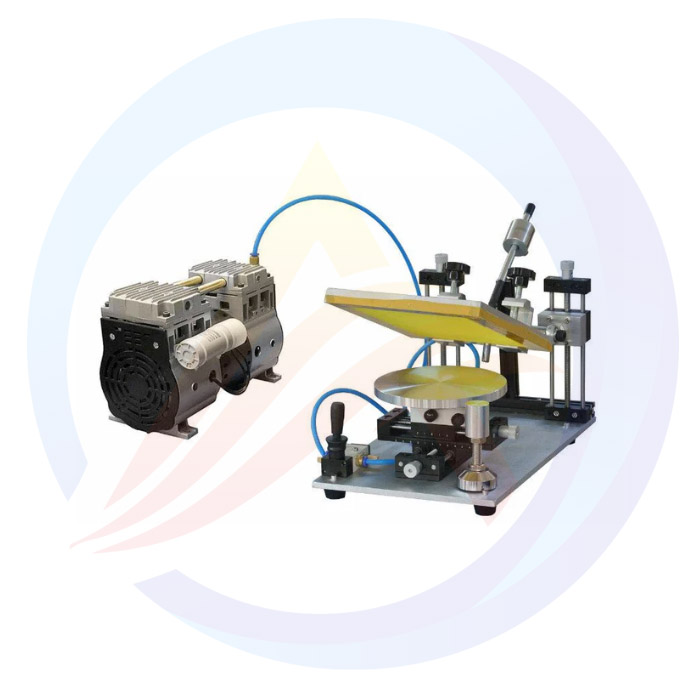

AOT-EQ-SPC-2 is a manually operated screen printing film & circuit coating unit. The coater has Max. 155 x 255 mm printing area with Dia.150mm precision position adjustable at three-dimension and vacuum chuck to load and unload substrate easily. It is an ideal tool to make pattern films in the research Lab.

Product model | AOT-EQ-SPC-2 |

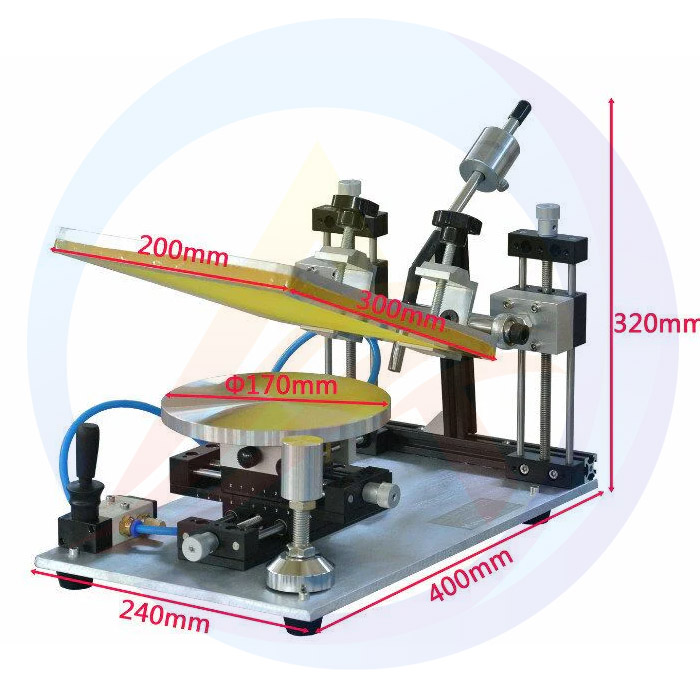

Sample holder | Dia.150mm sample stage

Sample is held by built - in vacuum chuck

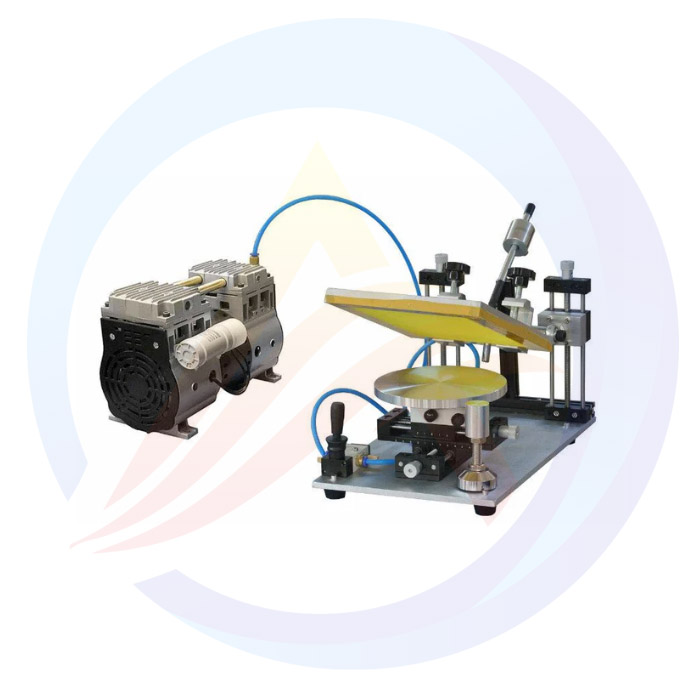

One small oilless vacuum pump is included for immediate use ( click underlined to see specs ) |

Position adjustment & accuracy | X: 0 - 13mm; Y: 0 - 63mm; Z: 0 - 60mm |

Screen Frame adjusting | ±20° adjustable |

Vacuumed area | 20×20mm |

Screen Frame size & Squeegee | Frame size: Outside: 300×200 (mm)

Max. Printing Area 155×255mm

Screen Frame size: mesh 200 (0.074mm) and mesh 420 (0.0296mm) are included. (Note: MTI doesn't supply the custom made silk - screen stencils, please source it from local suppliers)

One Scraper is included to apply printable material |

Input Power of the Vacuum Pump | AC 110/220 V 50/60Hz

Please select the voltage in options bar, 220VAC version doesn't include the power plug |

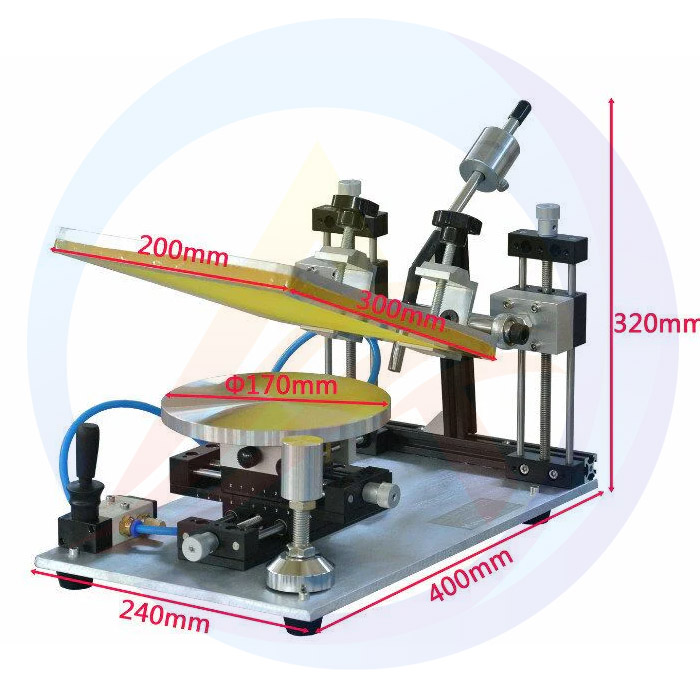

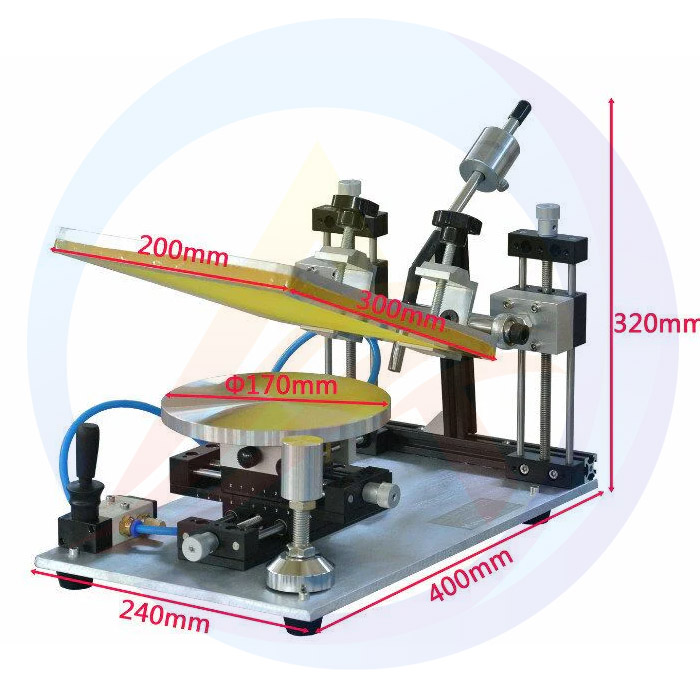

Dimension | 400mm L × 240mm W × 320mm H |

Coater Net Weight | 10 kg |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q:What is Screen Printing Coater

A: Screen Printing Coater is a device that uses a screen plate to hollow out patterns and squeezes the paste to coat the substrate with a scraper. The principle is to use the mesh screen to cover and hollowed-out areas, allowing the slurry to precisely adhere to form coatings or patterns. It is suitable for fields such as electronics, photovoltaics, and packaging, and can achieve micron-level precision. It is suitable for small-batch customized production, but its mass production efficiency is lower than that of the continuous coating process.

Q:The function of the screen printing coater

A:The function of a screen printing coatier is to evenly apply paste, ink, etc. onto the surface of substrates such as paper, metal, circuit boards, etc. through the hollowed-out areas of the screen plate with a scraper, forming specific patterns, coatings or functional layers. It can achieve micron-level precision and is applicable to fields such as electronic manufacturing (such as PCB solder mask layers, chip electrodes), photovoltaics (solar cell paste printing), packaging and decoration, etc., meeting the requirements of small-batch customization and high-precision coating.

Q:How to choose a screen printing coater

When choosing a screen printing coater, first determine the type based on industry requirements: The electronics industry needs high-precision screen printing coating machines, whose servo drive systems can achieve micron-level printing accuracy. In the packaging industry, high-speed pneumatic screen printing coater can be selected to enhance the efficiency of pattern printing. Secondly, the compatibility of the base material should be considered. For flexible materials, the screen printing coating machine needs to be equipped with a vacuum adsorption platform, while for hard materials, a screen printing coater with wear-resistant screens is required. Attention should also be paid to the control of coating thickness (adjusted through the mesh count of the screen and the pressure of the scraper), production capacity (the fully automatic screen printing coating machine is suitable for mass production), and after-sales maintenance to ensure that the selected screen printing coating machine meets the production requirements.