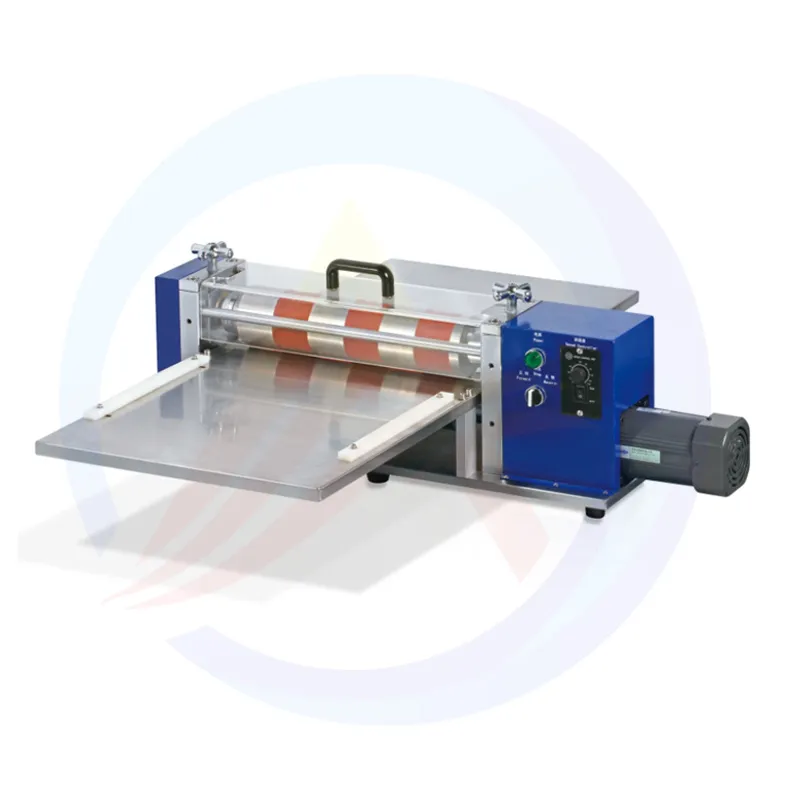

In the battery manufacturing field, lithium battery electrode slitting machines and slitting machine technologies have been advancing in recent years. To meet market demands, lithium battery manufacturers have introduced advanced slitting machines to optimize production processes. These machines, operating in workshops, precisely slit electrodes using high-precision cutting technology, enhancing battery performance and production efficiency. Their development aligns with the new energy industry trend, evolving from simple mechanical structures to intelligent control systems. Currently, the slitting machine market is promising but highly competitive, moving towards intelligence, automation, and eco - friendliness. This trend promotes the development of the lithium battery industry and the entire manufacturing sector.

2025-04-23

More